High Standards, Healthy Choices

Jane H.Why did you choose to switch to reusable menstrual products? Many make the switch because they want to live a more sustainable life or they are worried about potential toxic chemicals in their disposable products. According to the advocacy group Women’s Voices for the Earth, dioxins, furans, pesticide residues and other potentially harmful chemicals have been found in conventional pads and tampons. It’s natural to feel anxious about potential chemical exposure in your period products. Reusables are not exempt from this either, with increasing interest in the chemicals that may be found in technical fabrics.

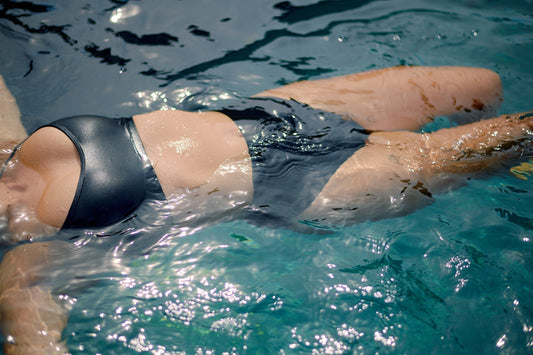

What is a sustainable fabric? For us, it is something that has a reduced carbon footprint, is made using traceable raw materials, and developed through strong relationships with our manufacturers to ensure transparency around chemical inputs and certifications. All four of these things drive our sustainability goals and today, we thought we’d take a walk through how our processes work together to produce what we believe is the world’s most sustainable period underwear. Let’s break it down.

Sustainable Textiles

Our underwear, including our Truetex™ gusset blend, draws from three major types of fibre: organic cotton, Tencel™ Lyocell and recycled polyester. These fibres have various properties that make our undies high performance powerhouses — wicking moisture, absorbing blood and generally creating the super-comfy experience we want for all periods. Making anything has an impact on our planet, and there are a lot of pros and cons to be weighed.

Organic cotton is grown without insecticides, pesticides and is not genetically modified. Choosing organic is particularly impactful for cotton, which covers just 2.5% of our planet’s total agricultural area, it uses 7% of all pesticides and 16% of all insecticides. Our Luna Undies relied on organic cotton; it was a sustainable choice but also had limitations. Cotton is absorbent, but heavy when wet, and organic cotton is lower yield, meaning its water consumption is significant.

To make our underwear even more high-performance, we explored Tencel™ Lyocell and recycled polyester. Polyester is essentially plastic and comes from a fossil fuel feedstock. Recycled polyester allows us to take garbage (in Aisle’s case, specifically pre-consumer waste — think plastic scraps from manufacturing) and convert it into something useful; it also means that we can take advantage of the quick drying and wicking properties of polyester. We also added Tencel™ Lyocell. Tencel™ is the brand name for Lyocell specifically produced by Lenzing. It is derived from trees, and is produced through a proprietary process that is closed-loop, minimizing chemical waste. Tencel™ is also more absorbent and breathable, two highly desirable properties.

Sustainable Processes

These sustainable textiles form the basis of a truly eco-friendly pair of undies. However, it’s not just about the textile, but the process that gets it there. Our fabrics use various certifications from the Control Union, certifying our organic cotton and recycled polyester, and Oeko-Tex® Standard 100, which is a chemical management certification. Oeko-Tex® Standard 100 specifically focuses on chemicals and dyestuffs used in the production of textiles and products, and covers more than 300 chemical substances. To receive the certification the component must pass specific testing through Oeko-Tex® site visits and tests throughout its entire production (from fibre, yarn to fabric to finished material). If no harmful substances are found, a certification and report are provided. This process can be completed for an entire product (where threads, buttons, and the garment production facility are considered) or for each individual material. Our certifications are at the material level. We designed our Truetex™ specifically to avoid the use of added chemical finishes, which are popular to change the properties of textiles. They’re not usually great for the planet, so we try and skip ‘em.

We also work hard to make sure that our production processes are ethical; we visit our factories, ask for compliance with a rigorous supplier code of conduct, to ensure worker safety and positive working conditions. We’re always evaluating our processes to ensure that we’re improving our sustainability practices through our supplier survey and regular conversations with vendors and industry experts.

Thinking Through Everything Else

Sustainability is a process. We think about how to reduce packaging, and try to ensure that the packaging we do use is recyclable. We want to learn more about the impact of our products, cradle-to-grave, and performed a life cycle analysis in 2020 to deepen that knowledge. (You can see the results in the ticker on our website!) We evaluate our carbon footprint every year; including eschewing air freight in favour of greener sea shipping. Where possible, we embrace a zero waste production process. Our attitude is every little bit helps, and we’re confident that we’re making a difference in shifting from a linear economy to something more circular.

What don’t we do? We don’t make claims like “our underwear is chemical-free”. For us, this smacks of greenwashing and is anti-science — the world is made up of chemicals, baby! — and we think that being sustainable is more than organic cotton or sustainable packaging. We’re committed to making the most sustainable undies possible, and that starts with being really real with what we do.